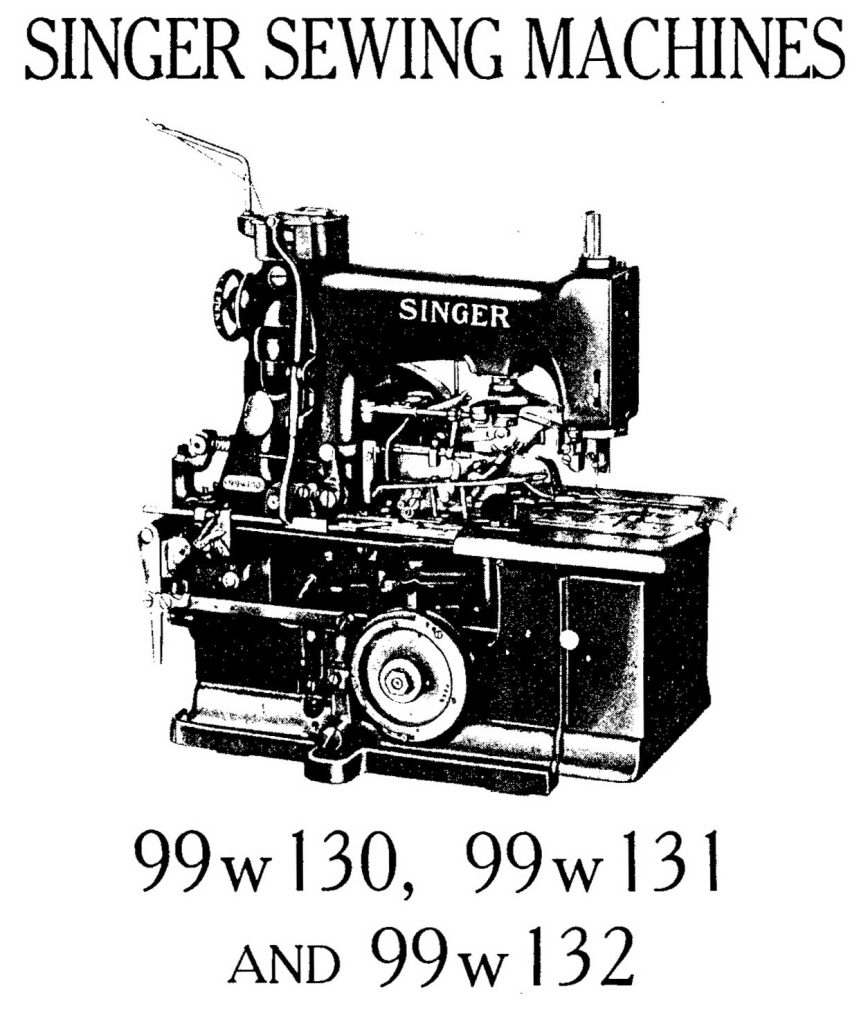

To Set Up the Machines

See Form 1875w, instructions for setting up machines on power tables with driving equipments.

Speed

The maximum speeds recommended for the shafts in Machines 99w130 to 99w132 are as follows:

Buttonhole Cutting Shaft – 185 to 200 revolutions per minute.

Stop Motion Shaft – 750 to 800 revolutions per minute.

(This will drive the arm shaft at a speed of from 1500 to 1600 revolu- tions per minute.)

The table shaft pulley sent out with the machine for driving the sewing mechanism and buttonhole cutting mechanism is made in various sizes, as listed below, for different speeds of table shafts. Care must therefore be taken to see that the table shaft pulley used is of the correct size to drive the stop motion shaft (Fig. 10) at a speed of 750 to 800 revolutions per minute and the buttonhole cutting shaft (K4, Fig. 8) at a speed of 185 to 200 revolutions per minute. The correct speed of the stop motion shaft should be ascertained by placing a speed indicator at the gear end of the rapid feed crank shaft. The speed of the rapid feed crank shaft should be about 1250 to 1290 revolutions per minute. See Fig. 10.

Shaft Pulleys

Safety Lock

To prevent accidental starting of the machine when threading, oiling or making adjustments, the machine can be locked out of operation by pushing the safety lock (T4, Fig. 8) under the start- ing rod (S4, Fig. 8), thus holding up the starting rod so that it cannot be depressed to start the machine. When finished thread- ing, oiling or making adjustments, it will be necessary to unlock the machine by swinging the safety lock forward from under the starting rod, before the machine can be started in operation.

Needles

Needles for Machines 99w130 to 99w132 are of the following Class and Variety Nos.:

| Class & Variety | Description | Style of Point | Sizes |

| 142 x 1 | for Cloth | Round | 13, 14, 15, 16, 17, 18, 19 |

| 142 x 5 | for Cloth | Round | 10, 12, 13, 14, 15, 16, 17, 18, 19, 21 |

| 142 x 6 | for Khaki | Spear Wedge | 17, 19 |

| 142 x 8 | for Leather | Reverse Spear | 17, 18, 19 |

¶ The size of the needle to be used should be determined by the size of the thread which must pass freely through the eye of the needle. The successful use of the machine will be interfered with if rough or uneven thread is used, or if it passes with difficulty through the eye of the needle. ¶ Orders for needles must specify the quantity required, the size, also the class and variety numbers separated by the letter x.

The following is an example of an intelligible order:

“50 No. 17, 142×1 Needles,” if for Cloth.

“50 No. 17, 142×5 Needles,” if for Cloth.

“50 No. 17, 142×6 Needles,” if for Khaki.

“50 No. 17, 142×8 Needles,” if for Leather.

¶ The best stitching results will be obtained in using the needles furnished by the Singer Sewing Machine Company.

To Determine the Proper Materials to Use forButtonholes which are Cut Before Sewing

¶ Stitch a buttonhole in the material to be tested, using the same lining and materials in the same layers and positions that they will occupy in a garment. Turn the slit of the buttonhole outward and grasp the purl between the thumb nail and the fore- finger and force the purl with the thumb nail toward the edge of the buttonhole. Repeat this several times, increasing the strain, and if the stitches (or purl) give or slide toward the edge of the slit it indicates that the material is not suitable for buttonholes which are cut before sewing. The thicker the material is, the wider the bight should be in the depth stitch from the button- hole slit.

Thread and Cord

¶ Either right or left twist thread may be used in the needle and looper.

When stitching buttonholes with silk thread, a heavier thread should be used in the looper than in the needle, for example: use B silk in the looper with A silk in the needle. ¶ When stitching buttonholes with cotton thread, regular but- tonhole thread is recommended. Harder finish thread should always be used in the looper than in the needle. This will facili- tate the formation of perfect stitches in the buttonhole. ¶ For the cord, medium size buttonhole cord will give the best results.